Creating More Storage Space in the Warehouse – Catwalks, Mezzanines, Vertical Shelving

Distribution centers are overloaded with high demand and see-sawing supply. Some products you can get plenty of; others have months-long backlogs.

If you're in a situation like this, you may have taken to ordering extra product, preferring to store the extras so you have them later.

The trouble is—where do you store all the product?

Two Ways a Warehouse Can Create Storage Space

In our experience, you can create more storage space in a warehouse two ways:

- Building 'Up' – Adding vertical levels to your existing rack/shelving.

- Leverage 'extra' space around current storage, including (limited) floor space.

In both cases, it's important to preserve safe passage for workers & equipment. We'll address this later, but first, let's talk about building 'up.'

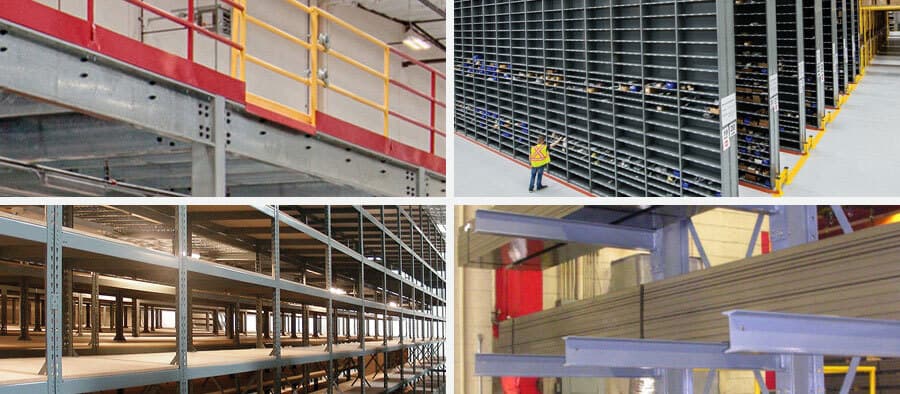

Most warehouses don't take full advantage of the vertical space they have. You can do it three ways – adding rows on top of vertical shelving, installing catwalks, or putting up a mezzanine.

Vertical Level 1: Add-Up Vertical Shelving

Many rack & shelving systems allow for second, and even third levels. The RiveTier boltless shelving system is one example.

When planning such add-ups, consider two elements: Warehouse ceiling height, and maximum stable weight.

For example: You may have a 20' ceiling in the warehouse, but your shelving system only goes up to 8'. You add a second level of vertical shelving, doubling to 16' high.

While this gives your team double the amount of storage space, it still allows clearance for airflow and emergency sprinklers. Plus, since the shelving system is capable of doubling its height, its maximum stable weight increases with the second level.

Vertical Level 2: Catwalks

Got some space across the top of your shelving? Install a catwalk across. They're meant for individual passage from unit to unit, though they can also serve as extra stacking space (as long as product stacking doesn't block passage).

If you put in a catwalk, or already have one & want to stack product there, remember these two warnings:

- Stack only along one side of the catwalk. Use the side closer to the warehouse's center, so all catwalks follow the same pattern.

- If you decide to stack product on catwalks, consider blocking them off to foot traffic entirely. (Just make sure you won't need access to the product in the middle of the catwalk for a while!)

Vertical Level 3: Mezzanines for Second-Story Storage

You can install mezzanines above certain shelving systems, or put in freestanding models. Either way, you'll add a second story of floor space, giving you a big flat space for extra stacking and/or additional shelving units.

Mezzanines take up the most warehouse space of these 3 options. You may need to either reorder your rack, or replace some of it with under-mezzanine shelving to accommodate one. If you have the vertical space though, they give you enormous room for storage.

As with catwalks, keep these safety warnings in mind:

- Stack along the mezzanine perimeter first.

- Never block the stairs, at top or bottom, even partially.

- Underneath the mezzanine, stack to the top! Use freestanding shelving in rows to leverage as much space as possible.

SPECIAL NOTE: Since catwalks and mezzanines don't allow for forklifts or pallet jacks, you only have two methods of delivering product boxes to them – Manual carry, and order pickers.

To reach mezzanine heights with an order picker, look for "High-Density" models like the Jungheinrich EKM202.

How to Leverage 'Extra' Space

Generally, one rack space takes one pallet/product box. This can sometimes leave a little open space to either side. Basically 'gaps' in the lower levels of rack.

That's one 'extra' space you can use. The other to consider is the floor space near existing rack.

To safely use the 'extra space,' follow these steps:

LOWER-LEVEL GAPS

- If you have a narrow vertical space between pallets where you cannot place shelving, stack product there! Stack boxes as high as the rack beside the space goes.

- By 'lower level' we mean floor-level and one level above. Stacking above these risks product falling on workers.

- Use the "brick stacking" technique with boxes. Turn each level of a stack 90 degrees from the one below it. This helps keep the stack stable, even if bumped. (This also works in narrow spaces.)

- Use shrink wrap around vertical stacks, to prevent slippage.

FLOOR SPACE

- Does your rack system include drive-up rack space? Fill this space, and then stack pallets in front of it.

- Temporarily blocking floor-level storage allows for more space without endangering product or blocking passageways.

- Use floor tape to mark the corners of extra stacks.

In both cases, document what product you've stored where. Chances are you do this already, but make sure to include the vertical stacks and their locations.

Preserving Safe Passage

Regardless of storage method, the big thing to remember is OSHA's central guidance (especially the bolded line):

Each employer –

Shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees.

From OSHA Act, Section 5, "Duties"

This means that, even if you're trying to use every square foot of storage space, we still have to keep the warehouse safe for workers to move through.

How do you do balance safety and efficiency when storage space runs thin? These tips should help.

- Walk the warehouse floor at least once a week. Watch for any of the following:

- Blocked exits or aisles.

- Product stacked above a catwalk or mezzanine's guardrails.

- Aisles with stacks on both sides, choking off passage.

- Workers stacking manually without proper PPE (including back braces).

- If you see an aisle with already-full racks, and you know you'll use floor-stacked product before sourcing from the racks, then you can stack pallets on the floor in front of ONE side of the aisle.

- Since you likely have picking routes in place already, add similar products along these same routes. If you're stacking extra product, this makes it easy for workers to retrieve it.

- Never exceed a rack's maximum weight limit at any level. It's too risky.

Have you built up your warehouse storage space already? Which method worked best for you?

Until next month!

Marshall Cromer, The Forklift Boss

Cromer Material Handling

Deal of the Month

2019 Jungheinrich EKS314 Order Picker – $26,452

For our April Deal of the Month, what better option than an order picker? This is an electric Jungheinrich EKS314 made in 2019.

The EKS314 has a 3000# capacity, with a 96/207 mast. This model only has 25 hours on it—it was a demo model!

The Cromer Service team has performed all maintenance, and put on a new warranty, making this one of the best deals in our inventory.

The price for this Jungheinrich order picker: Only $26,452.

Only need it for the next few months? You can rent this order picker for $1,650/month.

To pick up, call Cromer at 800.974.5438 and ask for the April Deal of the Month.