6 Forklift Parts that Break Often—and How to Make Yours Last Longer

Last month we talked about overlooked forklift parts, and the damage they cause when they break. Fortunately, most of those don't break often.

What about those forklift parts that DO break often?

We're not talking about regular wear and tear, like forklift tires. Instead, let's talk about certain forklift parts that break more often than they should, either due to improper use, or operator damage.

More importantly, let's talk about how to STOP these parts from breaking so much!

The 6 Forklift Parts that Break Frequently, and the Reasons Why

|

Seats and Seat Belts. Believe it or not, we see damaged seats & seat belts all the time! Operators unintentionally damage both of them during the workday. How? Normally, by leaving tools in their back pockets – box cutters, screwdrivers, etc. These gouge out holes in the seats and cut the seat belts. This can create safety issues for the forklift...and some operator discomfort. |

|

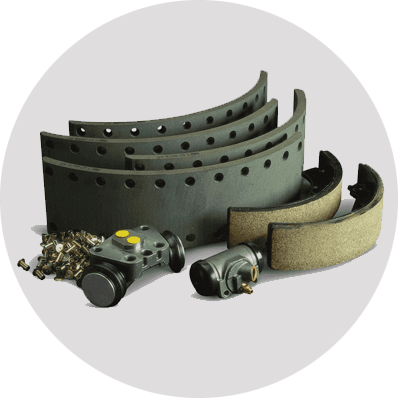

Brake Pads. Yes, brake pads will wear out no matter what. But improper operation can shorten their lifespan by months. Whenever operators stomp on the brakes, the brake pads wear down a little faster. Why would they stomp on the brakes? The same reason you might stomp on your car's brakes—your attention wavered for a moment, or someone stepped out in front of your vehicle. |

|

Forklift Tires. Anything that constantly carries loads like we do will wear out pretty fast. However, tires can wear down faster than expected from operator activity. Specifically, making quick turns and/or overloading the forklift. Of all the parts discussed here, excess wear to tires causes the most damage. The forklift's suspension will strain. Fuel economy will decrease. Excess wear damages its brakes, and its steering. The forklift can even buck its operator, causing injury. |

|

Oil Filters & Spark Plugs. These can burn out faster than you might think. Both are in use constantly while the forklift operates. Pushing a forklift for too long, or skipping maintenance, almost guarantees these will break down. When a spark plug dies, you'll have trouble starting the forklift, and/or sputtering of the engine while it runs. When oil filters fail, you risk overheating the engine, and even locking it up. |

|

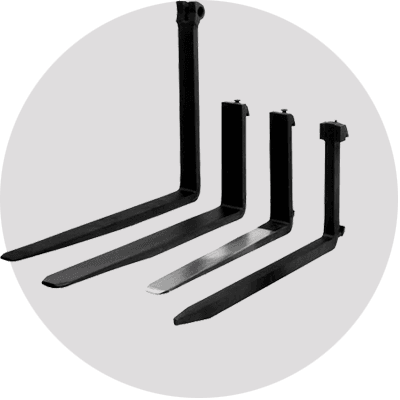

Forks. While reliably strong, you can bend or damage forklift forks relatively easily. How? By carrying uneven/imbalanced loads. Running into walls or racks. Even carrying too much weight for too long can bend forks. If a forklift has a 4,000# capacity, don't use it to carry 5,000# of product—not even once! |

|

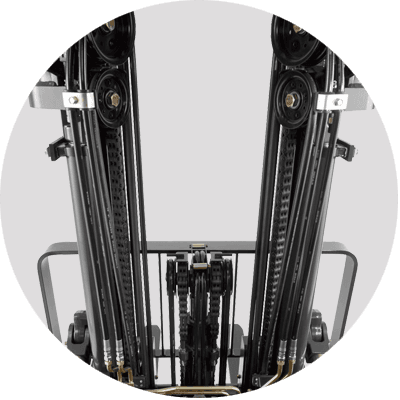

Mast Parts. A forklift's mast is very sturdy. Some of its parts however may wear each other out. The most common break we see on a mast comes from the chain wearing out a roller or bearing. You know when this happens—because it causes ear-splitting, metal-on-metal scraping! |

How to Prevent the Breaks Next Time

When a part breaks, you replace it. Instead of just waiting for it to break again though, how do we make these parts—and the whole forklift—last longer?

For Seats & Seat Belts: Notify all team members that seats & seat belts are safety items…and that you include them in safety inspections. Ask them to check their pockets before operating. You can use a seat cover to extend a seat's life as well. We carry a cover over on Forkliftboss.com that will do the job.

For Brake Pads: Brush up on safety training. Not just for operators, so they know to drive slowly and avoiding stomping on the brakes, but also for team members working around forklifts. They need a reminder not to get in a forklift's way.

For Tires: Make sure to inspect tires daily. If you see excess wear, check with that forklift's operators on their routes. They may need retraining.

(Pro Tip: When solid tires get within ¼” of the letters/tire size on the tire, they need replacing.)

Oil Filter & Spark Plugs: Stick to your maintenance schedule. The service technicians will replace both items when needed. No need to be concerned.

For Forks: Train operators on correct & incorrect driving practices. For example, driving with the forks tilted down and not angled back, as well as elevating forks off the ground for accurate ground clearance.

For Mast Parts: Keep the mast chain well-lubricated. Make sure to inspect the entire mast when conducting regular maintenance. If you find scratches or a roller or bearing, replace it now so you reduce any related damage. Not to mention that horrible scraping sound.

Since we all need our forklifts to run as smooth as possible, for as long as possible, we can't have broken parts. Trust the old adage – "An ounce of prevention, a pound of cure."

Training and maintenance act as that "ounce of prevention" for all parts of the forklift. Let's use them and stay productive.

Until next month!

The Cromer Team,

Cromer Material Handling