How Electric Forklifts Save Money on Fuel and Maintenance

In our September newsletter, we talked about costs per hour in operating a forklift. But we didn’t talk about one cost in particular: fuel cost.

Fuel, even more than maintenance, illustrates just how much of a cost savings the electric forklift gives you over LPG trucks. That’s what we’re talking about this month.

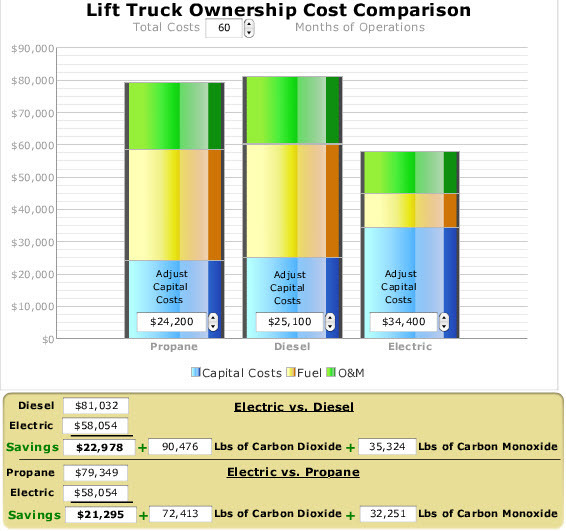

For a visual example, let’s head back to an old friend – the EPRI Lift Truck Comparison Calculator.

We’ve put in up-to-date energy rates for California. The calculator will use a 4,000-lb. forklift, operating for 8 hours a day, 5 days a week.

These are the results we get:

Look at the fuel difference. Over 5 years, an electric forklift needs about $10,000 in fuel/electricity. Propane needs over $30,000 in fuel. Diesel needs close to $40,000!

Want to know how much you’d save with an electric forklift? Grab your PG&E bill and look up the cost per kilowatt. (At time of publication, it’s $0.136/hour in California.) Adjust the “Electricity Price $/kWh” slider to match. Move the “Propane Price” or “Diesel Price” sliders to match your current fuel price. You’ll see the difference right away.

The other sliders factor in forklift usage, total operating time, and maintenance costs. Play with the sliders to see how the costs translate. You may find some justification to switch to electrics.

Maintenance: No Need to Replace Parts that Aren’t There

What happens if a forklift’s transmission begins to fail? The engine works harder to keep going. Burning excess fuel, causing more wear, and increasing the maintenance cost that’s coming up.

What happens if an electric forklift’s electricity flow gets disrupted? The forklift will typically shut down and need a quick repair.

This is just one example of the maintenance differences between forklift types. Differences which can add up to big cost savings.

Consider one of the biggest parts of forklift maintenance: Parts replacement.

An LPG forklift has an internal combustion engine. That means it has sparkplugs, plug wires, a distributor with a distributor cap, and oil. All of which need replacement over the life of the forklift.

Electrics don’t have those parts. They have a battery and a drive motor. No radiator, no coolant hoses, and no fan belts either. Fewer parts to wear out.

Fuel and Maintenance Add Up to High Cost over Time – or High Cost Savings, Depending on Your Forklifts

An LPG pneumatic-tire forklift costs less up front than an electric lift truck. But the LPG pneumatic has a higher cost than an electric, over time. The differences in fuel costs and maintenance needed spell out a big savings for electrics.

We hope this information helps you save on your next forklift purchase. Happy Thanksgiving!

Until next month,

Marshall Cromer, The Forklift Boss

Cromer Material Handling

Special Notice – Section 179 is Back! Huge Tax Savings on Material Handling Purchases

Last December we told you about the tax savings of Section 179 – a tax deduction you can take on equipment purchased OR leased. If you make your purchase before the end of the year.

The Section 179 deduction is good again for this year, tax year 2016. Plus, the 50% bonus depreciation is valid through 2019.

That means you have until December 31 to buy or lease equipment. All of the following qualifies for Section 179:

- Computer hardware or software

- Industrial Equipment (like our forklifts, rack & shelving)

- Office furniture and office equipment

- Vehicles used for business

You can find more details out at Section179.org.

If you want to take advantage of Section 179 tax savings, don’t want. Come out to any Cromer location for your end-of-year material handing purchases. We have everything ready to go.