The Best Forklifts for Use in Distribution Centers

We talk often about good forklift choices for warehouse environments. But what about a distribution center? Does the 'best' equipment for one translate to the other?

Maybe not. So let's talk about it.

Knowing the Right Equipment Always Helps Purchases

We've talked about forklift options for many years. Why pay attention to this question now?

Because it looks like the supply chain will have trouble with manufacturing & shipment for a while. In an effort to get enough equipment for moving product (especially at a super-fast pace), handling facilities might try grabbing whatever they can. Even if it's not a good fit for their environment.

However, if we know what's good and what's bad for their environment, we can make smart decisions even with limited equipment supply.

The Difference between a Warehouse & a Distribution Center

Most of the time we don't differentiate between a warehouse and a distribution center. Doing so today helps us identify which forklifts work better.

Let's use these two factors for differentiation:

- Warehouse receives product; DC packages & ships it to customers.

- Warehouse is to store; DC is to deliver.

Obviously exceptions exist on both sides! But this is simple enough to work with for this article.

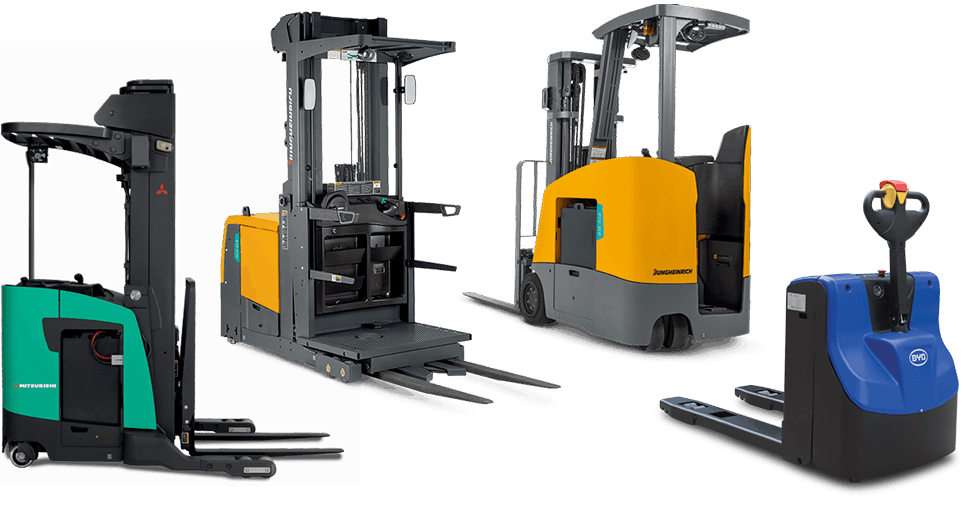

Material Handling Equipment You SHOULD Use in a DC

Distribution centers are a hotbed of activity. They have to keep moving. Any equipment they use cannot slow the workflow down.

Based on this requirement, let's list out material handling equipment DCs should use for fast, easy movement.

We'll split them out by role in a distribution center's typical workflow:

- FOR SORTING & PLACING – Narrow aisle forklifts

- Since you operate these standing up, you have no restrictions on operation. Step on, activate, and go.

- Since you operate these standing up, you have no restrictions on operation. Step on, activate, and go.

- FOR INVENTORY – Multi-directional Reach Truck

- A versatile option for bringing just about anything, just about anywhere.

- A versatile option for bringing just about anything, just about anywhere.

- FOR ORDER PREPARATION – Order Picker

- The first choice for fulfillment, as it has been for many years!

- The first choice for fulfillment, as it has been for many years!

- FOR PACKAGING – Electric pallet jacks

- Since DCs can experience sudden rushes to fulfill orders, it pays to keep electric pallet jacks in supply. They move faster, turn easier, and take less effort to operate than manual pallet jacks.

- Since DCs can experience sudden rushes to fulfill orders, it pays to keep electric pallet jacks in supply. They move faster, turn easier, and take less effort to operate than manual pallet jacks.

- FOR SHIPPING – Rider pallet jacks, or cushion-tire forklifts

- Since you're moving product out of the DC for shipping at this stage, the right tool is the one that can handle the available load. Sometimes a rider jack will do the job the quickest. However, for heavier loads, you may need a standard forklift to load the truck/container.

Material Handling Equipment You SHOULD NOT Use in a DC

Even if you have these forklifts available, they aren't the best choice for distribution center workflows.

Pneumatic Tire Sit-down forklifts – While very common in warehouses, using these in a DC isn't the most efficient choice. That's because these are sit-down forklifts, which means getting up and down many times throughout the day. In a fast-paced distribution center, you risk a safety infraction and/or worker fatigue this way.

Rough Terrain forklifts – Distribution center floors are smooth, easy to walk, and easy to move materials along. Rough Terrain forklifts aren't designed for this! They're better off outdoors, where the ground is uneven. Using a rough terrain forklift indoors puts the operator—and everyone around them—at risk of the forklift slipping and crashing.

Diesel-Powered forklifts – While all forklift manufacturers take pains to make their trucks as clean-burning as possible, you don't want diesel fumes building up indoors all day!

Work Fast with Your Equipment—But Don't Push It, For Safety's Sake

While all of the equipment options here emphasize speed, we want to end the article with one strong caveat. No worker should try to 'race' their equipment.

By that we mean, no one should push their equipment as fast as it can go, as often as they can. Not only does this harm the equipment, but more importantly, it puts whole teams at risk of accident.

We hope these recommendations will help DCs reach & sustain maximum efficiency.

Until next month!

Marshall Cromer, The Forklift Boss

Cromer Material Handling

Deal of the Month

2016 Doosan B18T-5 Forklift – $23,900

For our June Deal of the Month, we have a used electric that fits well in a warehouse, distribution center, or anywhere else. This is a Doosan B18T-5 electric forklift, made in 2016.

This model is an electric sit-down, with a 3,500# capacity, and a triple-stage mast. These will take just about every load you need to, and run all shift long with no surprises. Plus, this model has only 520 hours on it!

The price for this Doosan electric: Only $23,900.

To pick it up, call Cromer at 800.974.5438 and ask for the June Deal of the Month.